FOYCOM Warehouse Management System For Wholesale Business

Optimizing Your Warehouse Strategies for Efficiency, Safety, and Success of Wholesale Business.

Reasons Why Wholesale Businesses Need Warehouse Management Solution?

Effective warehouse management is crucial for any business involved in the supply chain. At FOYCOM, we understand that the seamless handling of physical goods directly impacts customer satisfaction and overall profitability. Warehouse management involves a set of processes that govern the storage of goods and their efficient movement across the warehouse to ensure timely customer fulfillment.

The Best Wholesale Warehouse Management Software Can Help With:

-

Track the flow of stock from the receiving end to dispatch, keeping stock levels up-to-date.

-

Manage expirations, damages, and returns to keep inventory in good condition.

- Organize a large inventory for easy and accurate picking, packing, and shipping.

-

Regularly check inventory turnover rates to spot slow-moving items and adjust stocking and purchasing strategies as needed.

-

Get a clear picture of stock positions to make smart decisions.

-

Define reorder levels for each product to avoid running out of stock or overstocking.

Features of FOYCOM Warehouse Management System

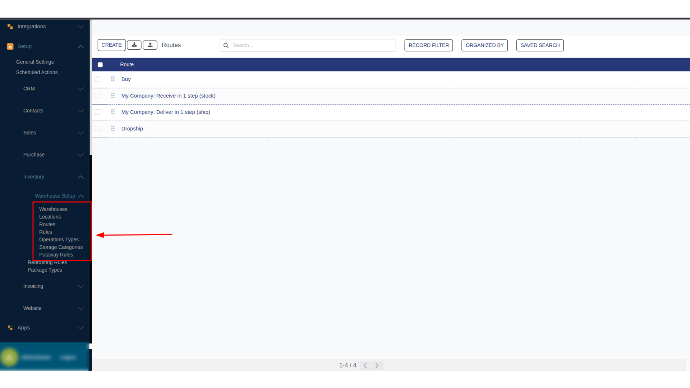

Warehouse Location Management

Efficiently handle incoming goods with automated tracking and quality checks. Streamline receipt, inspection, and recording to enhance accuracy.

Goods In Processes

Efficiently handle incoming goods with automated tracking and quality checks. Streamline receipt, inspection, and recording to enhance accuracy.

Order Management

Oversee the entire order lifecycle from creation to fulfillment. Manage order statuses, prioritize tasks, and ensure timely processing.

Shipping Management

Optimize the picking and packing process with intuitive workflows. Improve accuracy and speed by automating and organizing tasks.

Order Picking and Packing

Optimize the picking and packing process with intuitive workflows. Improve accuracy and speed by automating and organizing tasks.

Returns Management

Handle returns smoothly with automated processing and tracking. Streamline return requests and manage restocking efficiently.

Auto Calculate Quantity Of Product Based On Amount/Case

Automatically calculate product quantities based on case amounts for accurate inventory management. Simplify stock level adjustments and reporting.

Internal Transfer

Facilitate internal product transfers between locations with ease. Track movements and adjust inventory levels to maintain optimal stock.

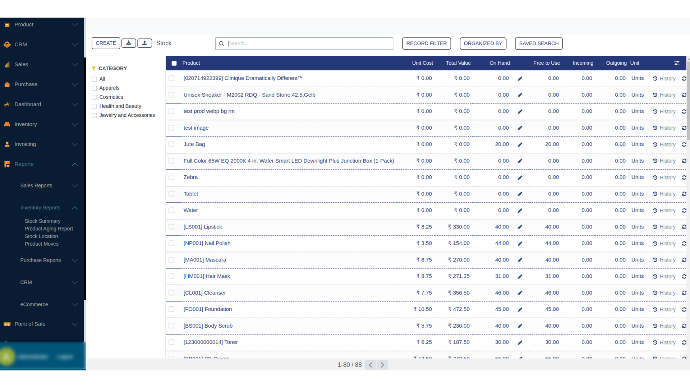

Physical Inventory

Conduct regular physical inventory checks to ensure stock accuracy. Reconcile discrepancies and update records to reflect actual inventory.

Scrap

Manage and record scrap materials efficiently. Track disposal processes and adjust inventory to account for waste and losses.

Landed Cost

Calculate the total landed cost of inventory, including shipping, duties, and other expenses. Gain insights into true product costs for better financial planning.

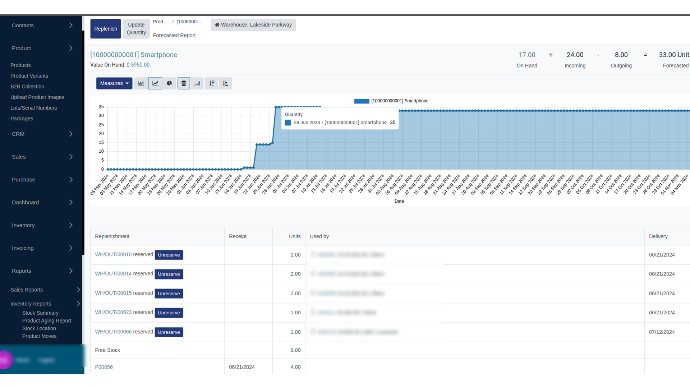

Replenishment

Automate inventory replenishment based on predefined thresholds and trends. Ensure optimal stock levels and prevent stockouts or overstock situations.

Benefits of FOYCOM Warehouse Management System

Optimized Space and Lower Operating Expenses

Maximize warehouse space utilization and reduce operational costs through efficient layout and inventory management. Streamline processes to cut down on overhead expenses.

Effective Labor

Enhance workforce productivity with streamlined workflows and automated tasks. Reduce manual errors and optimize labor allocation for increased efficiency.

Effective Shipment Management providing better Customer Service

Improve shipment accuracy and timeliness, leading to higher customer satisfaction. Track and manage shipments effectively to meet delivery expectations consistently.

Inventory Visibility

Gain real-time insights into inventory levels and locations. Make informed decisions with accurate data on stock availability and movement.

Internal Automation Benefit

Automate repetitive tasks and internal processes to boost efficiency. Reduce manual intervention and streamline operations for smoother workflows.

Ongoing Improvement

Continuously enhance warehouse operations through regular updates and feedback. Implement best practices and adapt to evolving needs for sustained performance improvement.

Advanced Features Of FOYCOM Warehouse Management System

Use Barcode Technology For Inventory Tracking

Implement barcode systems for accurate and efficient inventory tracking using FOYCOM wholesale ERP. Enhance data capture and reduce errors in product handling and management.

Automate Inventory Review

Automate inventory reviews to maintain accuracy and detect discrepancies early. Adjust stock levels and processes based on real-time data and trends.

Why Choose FOYCOM For Wholesale Business Warehouse Management?

Comprehensive Solutions

FOYCOM offers a full suite of warehouse management features that cover all aspects of your operations. Benefit from integrated solutions designed to streamline and optimize every stage of the warehouse process.

Advanced Technology Integration

Leverage cutting-edge technology with seamless integration of RFID, barcode systems, and real-time tracking. FOYCOM helps to stay ahead with advanced tools that enhance accuracy and efficiency.

Customized Solutions

Tailor FOYCOM’s systems to meet the unique needs of your business. Enjoy personalized configurations that align with your specific operational requirements and goals.

Proven Track Record

Benefit from FOYCOM’s extensive experience and success in the warehouse management industry. Rely on our established reputation for delivering reliable and effective solutions.

Focus on Efficiency

Maximize operational efficiency with FOYCOM’s streamlined processes and automation features. Reduce manual tasks and optimize workflows to boost overall productivity.

Safety and Compliance

Ensure safety and regulatory compliance with FOYCOM’s robust management features. Protect your workforce and adhere to industry standards effortlessly.

Continuous Improvement

Stay competitive with FOYCOM’s commitment to ongoing updates and enhancements. Embrace new features and best practices for sustained performance improvements.

Scalability

Grow with ease using FOYCOM’s scalable solutions that adapt to your evolving business needs. Expand your warehouse capabilities without disruption or added complexity.

Customer Support

Receive exceptional support from FOYCOM’s dedicated customer service team. Get timely assistance and expert guidance to ensure smooth operations and quick resolution of any issues.

FAQ Related to FOYCOM Warehouse Management Software

Warehouse management in a Foycom wholesale ERP system involves overseeing and controlling the storage, movement, and processing of inventory within a warehouse. It includes tasks such as receiving, picking, packing, shipping, and inventory control.

Effective warehouse management helps wholesale businesses optimize space utilization, improve order accuracy and fulfillment speed, reduce operational costs, enhance inventory visibility, and streamline overall warehouse operations.

Key features include: - Inventory tracking: Real-time monitoring of inventory levels and locations within the warehouse. - Order fulfillment: Efficient picking, packing, and shipping processes to fulfill customer orders. - Receiving and putaway: Streamlined processes for receiving incoming goods and placing them in appropriate storage locations. - Cycle counting: Regular inventory audits to ensure accuracy and minimize discrepancies. - Barcode and RFID scanning: Technology to automate data capture and improve accuracy. - Labor management: Tracking and optimizing workforce productivity and performance. - Reporting and analytics: Generating reports on warehouse operations, inventory levels, and order fulfillment metrics.

A wholesale ERP system optimizes order picking and packing by generating pick lists, guiding warehouse staff to the correct locations, and ensuring efficient packing processes. It may also support batch picking, wave picking, and zone picking to streamline operations.

Warehouse management in a wholesale ERP system can handle multiple warehouses by providing centralized control and visibility over all locations. It enables inventory transfers between warehouses, tracks stock levels at each location, and ensures coordinated operations.

Strategies include: - Layout optimization: Designing warehouse layouts to maximize space utilization and minimize travel time. - Cross-docking: Moving goods directly from receiving to shipping to reduce handling and storage time. - FIFO and LIFO: Implementing First-In-First-Out or Last-In-First-Out inventory management techniques. - Slotting: Strategically placing items in the warehouse based on demand and picking frequency. - Lean warehousing: Eliminating waste and inefficiencies in warehouse processes.

Warehouse management in a Foycom wholesale ERP system manages returns by processing returned goods, updating inventory levels, and tracking reasons for returns. It also supports reverse logistics by coordinating the return of goods to suppliers or reconditioning for resale.

Yes, warehouse management integrates with other business processes such as inventory management, order processing, accounting, and customer relationship management (CRM). This integration ensures seamless data flow and coordinated operations across the entire business.

Challenges may include: - System complexity: Ensuring the ERP system is user-friendly and manageable for warehouse staff. - Data accuracy: Maintaining accurate and up-to-date inventory data across all warehouse locations. - Technology integration: Integrating the ERP system with existing warehouse equipment and technology. - Change management: Training staff and encouraging adoption of new warehouse management processes. - Scalability: Ensuring the system can scale to accommodate business growth and changing requirements.

Wholesalers should consider factors such as scalability, integration capabilities, industry-specific features, user interface, support and training options, and total cost of ownership (including implementation and maintenance costs) when selecting an ERP system for warehouse management.